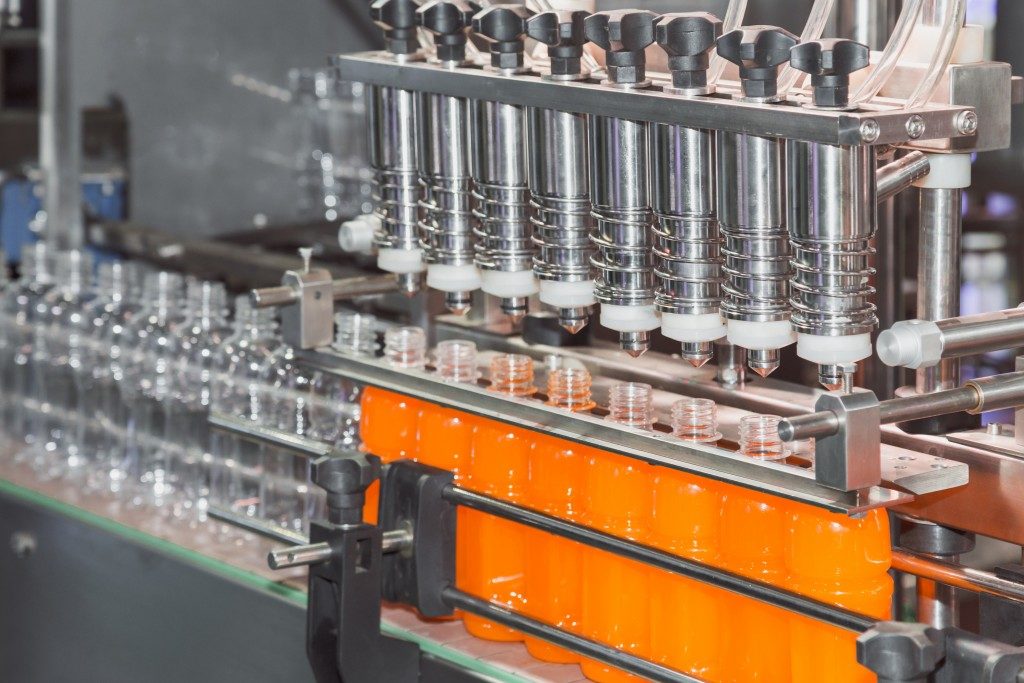

Different industries use filling machines for varying production requirements. They could use the equipment to process food, beverage, cosmetics, household or industrial products, and pharmaceuticals, among many others. As part of an industry supplying the growing demand for these products, how do you meet market needs without sacrificing your revenue?

Here’s how to tell if your current filling systems are still working for you, or if it’s due for an upgrade.

Finding the Right Equipment

Increasing production without overspending is possible. One way to do this is to invest in a filling machine that prioritizes production quality, speed, and precision. Choosing the right filling equipment for your business will help maximize production and minimize costs.

Filling machines vary in type and size, depending on their function. When you identify which filling equipment suits your operations, you’ll be able to determine if an upgrade is necessary.

If your current filling systems are underperforming in quality and quantity of production, it may be time to change your equipment. As production demands escalate in the manufacturing industry, you have to keep up by replacing machinery when these no longer work as fast or as efficient as needed.

Conducting a Thorough Audit of Your Existing Equipment

Are your current filling machines costing you more money in terms of maintenance and repairs instead of bringing in more revenue? If yes, it may be time to look for better performing machines.

A thorough audit of your existing equipment allows you to see performance issues, if there are any, with your machine before you begin production. By doing this, you are saving yourself from losses mid-production. Conducting routine audits of your machines will also help you determine whether a replacement is due.

If upgrading your current equipment than clinging onto your old machine, which costs more in repairs, will help you save more money in the long run, an upgrade of your system would be a wise move.

Check for Optimum Machine Usage

When there’s a significant decline or a stagnant value of production rates, your machine is no longer working the way it used to. In the manufacturing industry, it’s important to have machines used to their full capacity to get your money’s worth. Otherwise, you might want to consider replacing the machine with a new one. Get efficient equipment that delivers, returns profit more than it costs, and produces quality products.

New equipment may also allow you to prevent contamination during production. Heavy usage and lack of inspection protocols could leave filling equipment open to bacteria. Microorganisms may jeopardize the safety of your products, putting your consumers in harm’s way. Whether you process food or pharmaceuticals, sanitized filling machines are crucial to your products’ integrity.

A lot of factors help increase revenue. Installing quality filling systems is one. Recent developments in the industry showcase a number of filling machines optimized for every aspect of the manufacturing business. Upgrade your machine to keep up with the innovation in processes, increase productivity and improve quality, and you’ll eventually increase revenue.